I’m pleased to release a new publication in the Twenty-Second International Conference on Composite Materials (ICCM22) entitled “Enabling Biomimetic Morphing UAVs” with colleagues at SRI, the University of Southern California, and NextGen Aeronautics.

This publication details one application of a technology I have helped develop with my colleague Roy Kornbluh at SRI: ultra-lightweight, ultra-low power, electrolaminate clutches and mechanical multiplexers for reconfigurable systems in aerospace, astronautical, and terrestrial robotic applications.

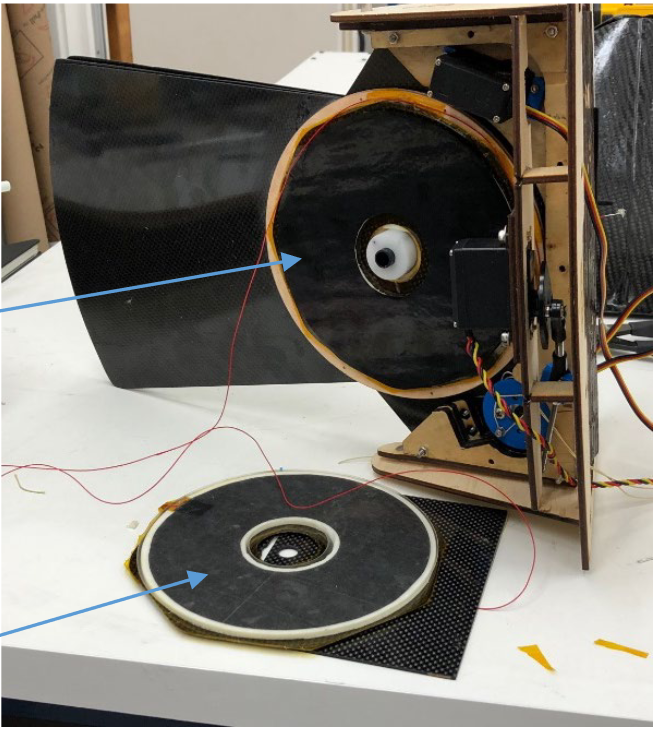

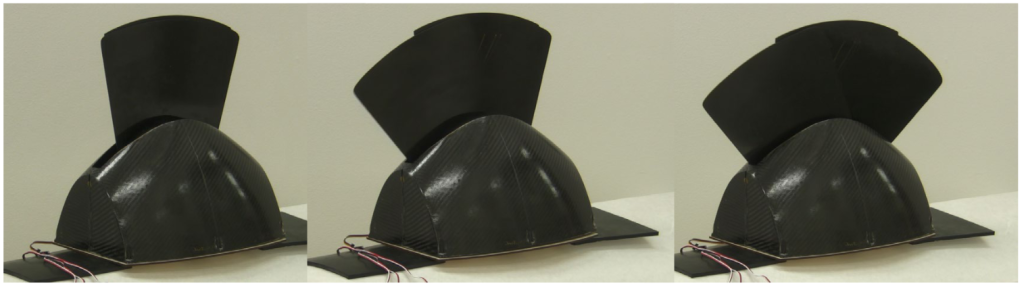

My role in this project was to mechanically design a demonstrator tailfin assembly using these new lightweight, low power, electrolaminate clutches to lock control surfaces of aerial vehicles into variable area configurations. I did all the mechanical and electrical design as well as composite fabrication of the carbon fiber tail and rear fuselage assembly.

Abstract: This paper reports on the design and testing of a practical, morphing wing aircraft. We intentionally mix and match elements of avian inspired design with novel technologies and proven mechanical components to provide a demonstrator aircraft that shows, in the simplest way, what benefits accrue from basic morphing changes. The simplest and most beneficial morphing concept is to change the wing area and aspect ratio, and it is easy to show that, for an otherwise fixed example configuration, a factor of three decrease in wing planform area can sustain a predicted lift:drag ratio, L/D = 9, when the vehicle flight speed U doubles from 12 to 24 m/s. Without morphing, L/D would be 6.5. Such a large area change can be achieved with a telescoping wing, which is not biomimetic, but is practicable and achievable using standard and custom 3D printed components. We combine this variation with a tail-body configuration that is bio-inspired, and suggested by previous and continuing work on the vehicle-level flight efficiency of tailless aircraft, where a standard tail geometry is replaced by a trailing edge flap that converts the cargo-carrying body into a lifting body. The practical shape-changing is enabled by the use of novel electrolaminate materials that can quickly change stiffness at varying positions/postures.