I make things, and fix things others have made. To do this I employ a very well rounded familiarity with diverse branches of science and engineering including cell biology, robotics, materials science, electrical and mechanical engineering, programming and automation, and state of the art fabrication capabilities like CNC machining, EDM, and 3D printing.

I’ve built brain-control interfaces for prosthetic robotic arms, new robotic grippers, new types of aerospace actuators, and custom scientific instruments to measure exotic phenomena in diverse industries spanning domestic utility companies to aerospace giants.

Some things I’ve helped fix are Delta IV heavy lift rocket motor gimbals, small research nuclear reactors, titanium manufacturing acid-pickling bath process controls, and the lighting in the flagship Apple store in Beijing China.

Below are a selected subset of notable projects:

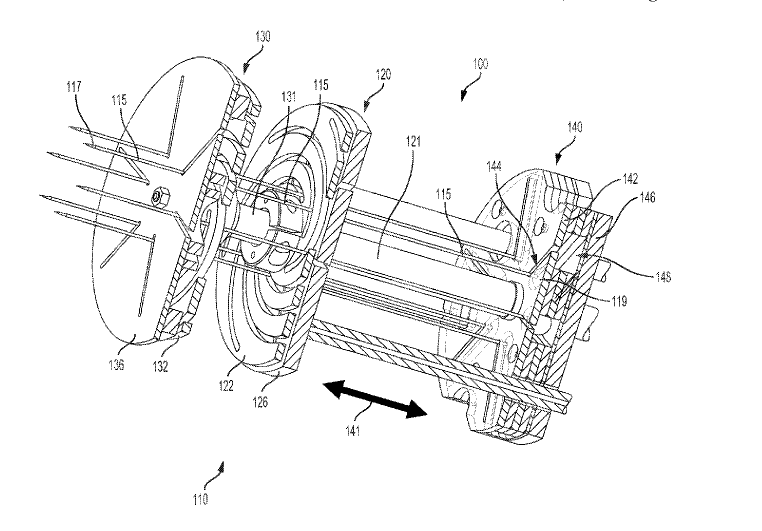

- US Patent 10,710,247 Issued for new robotic tool: “Conical Iris Gripper”. I was given an open ended problem – how to robotically grasp diverse food substances. I developed a novel concept, prototyped it, saw it put into use as the main robot gripper of the project, and got a patent out of it.

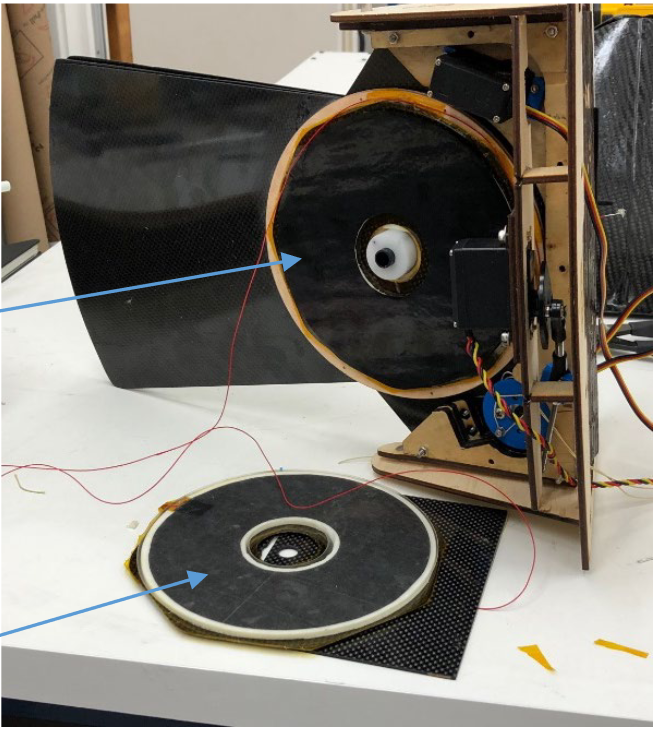

- Electrolaminate Multiplexed Morphing Tail Assembly for a novel drone – I designed and fabricated a lightweight, carbon fiber, tailfin assembly for a small demonstrator aircraft to showcase a new electrolaminate clutching technology.

Internal structure of prototype electrolaminate clutched tailfin assembly I designed and built - Magnetic Permeability Scanner – (see photo of Delta IV rocket at top) I designed and fabricated, then used, a custom sensor and positioning system to identify magnetic property anomalies within a damaged LVDT sensor core, and by doing so identifed the proximate and ultimate failure modes. This critical information, delivered on an very short timeline (3 days) ultimately allowed the client, United Launch Alliance, to make an informed decision to launch of a multimillion dollar weather satellite.

- Ultrasonic Concrete Thickness Monitor – I built an ultrasonic thickness gauge to continuously measure the thickness of poured ultra-high-performance concrete, for a high performance concrete casting factory.

- Automated Multi-Liquid Dispensing Apparatus – I built a relay-based industrial controller to regulate the sequencing and proportioning of reagent dispensing in a high performance concrete casting factory.

- US Patent 8154279 issued for novel graphitization corrosion sensor

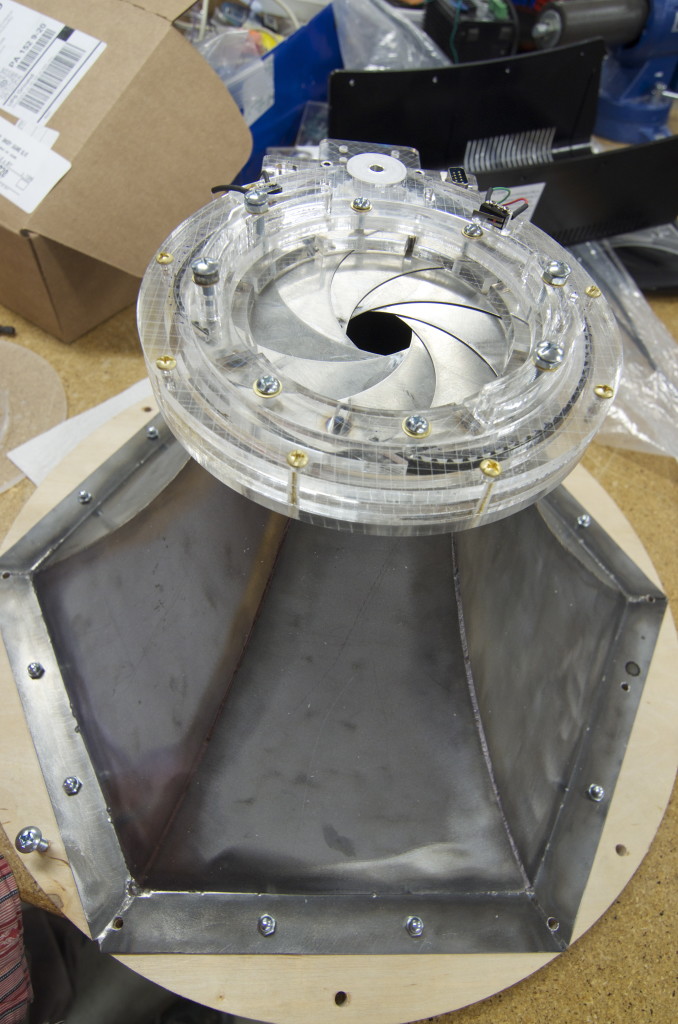

I was confronted with a client’s challenge of non-destructively detecting a subtle but catastrophic failure mode in cast iron municipal pipes. I led a team which designed, built, tested, and deployed a new sensor, which was awarded a patent. - A smoke-ring launching robot – I thought it would be neat if I had a gimbal-mounted cannon that could launch smoke rings across a room, (possibly useful for teleconferencing if you want to get someone’s attention, or general mischief). I designed and fabricated a heavyweight robotic gimbal, a welded exponential vortex-nozzle, and for good measure built a stainless steel iris to enclose the nozzle while it charged with fresh smoke. Hilarity ensued.

- Acid Pickling Bath Process Controls – I designed and installed a highly accurate acid-pickling material removal rate sensor system for Timet Titanium Factory

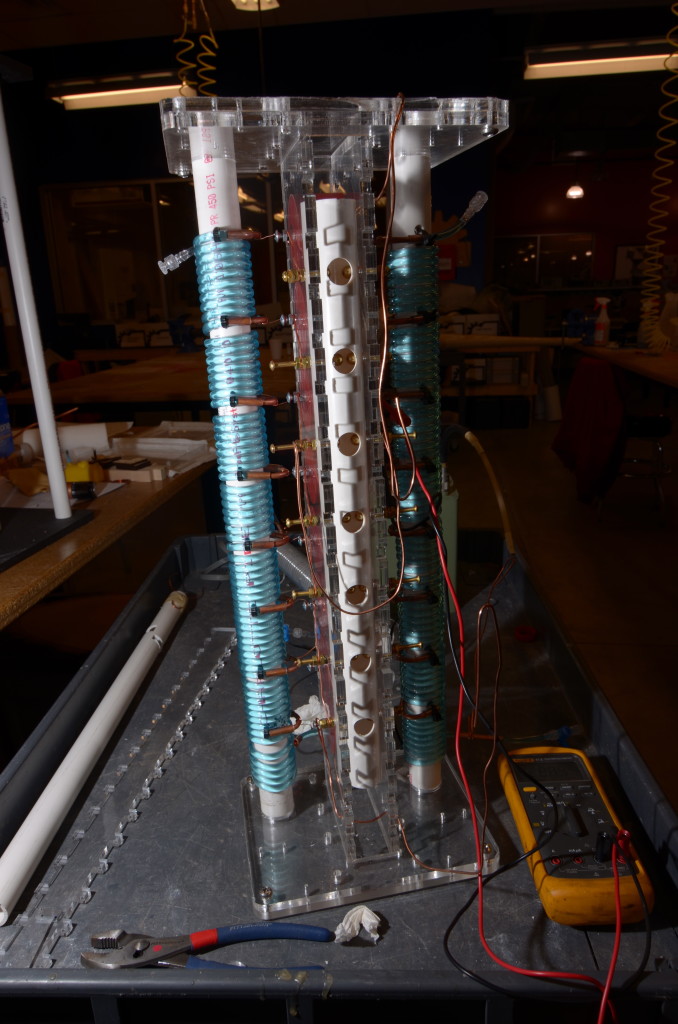

- 240kV, 8-joule impulse , optically triggered Marx Generator: For my personal interest in photographing high voltage phenomena, I designed and built (using inexpensive materials), a very very high voltage (a quarter million volts), low impedance, remotely triggered, electrical pulse generator capable of producing deafening, brilliant, 10″ long sparks and peak powers on the order of hundreds of kilowatts. – for the Electrified Flowers of Hawaii Project

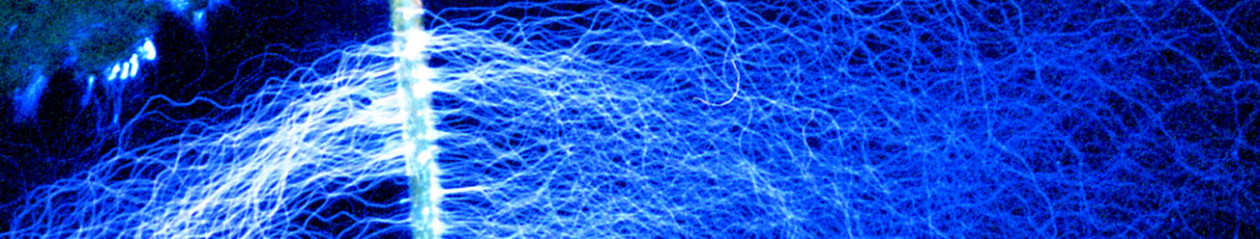

A 240,000 volt pulsed DC high voltage machine I built for the purpose of taking photographs of the corona discharge from leaves

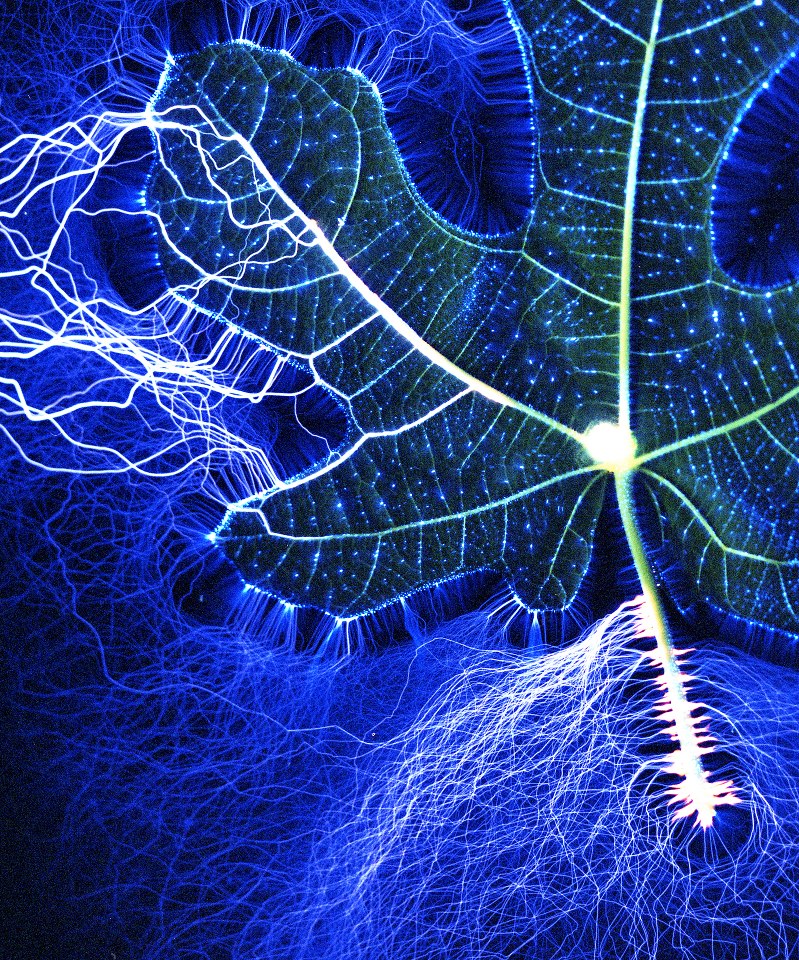

A portion of a 16×20″ photograph I made using the above lightning machine to energize this fig-leaf. - 60 gram, 1.2″ gap, feedback-controlled repulsive mag-lev system – A client was interested in making a levitating golf-ball for a levitating tee system. I designed and prototyped an electromagnetic suspension system capable of lifting a golf ball.

- Electrochemical Scanning Microscope – A forensic investigation of a defective medical device inspired me to design and build a new instrument to map highly localized anodic and cathodic zones on a cobalt-alloy prosthetic hip joints.

- Real Time Neural Control Algorithms for Prosthetic Robotics –

As part of my graduate study I built analog electronics and wrote C-code for a real time brain-computer-interface that was used successfully by Rhesus monkeys to control a prosthetic robotic arm, which they used to grasp and feed themselves tasty orange slices (while their uninjured non-robotic arms were gently restrained).

- Federal Class Action Suit Forensic Engineering Support –

as a materials science consultant I provided laboratory testing services and expert testimony for a multimillion dollar lawsuit over the corrosion issues surrounding a widely used product. - Custom Flux-Gate magnetometers – I designed and built a custom flux-gate magnetometer to achieve the highest possible sensitivity of magnetic field testing, in support of a project to develop embedded corrosion monitoring sensors for bridges.

- Kirkwood Bubble Iris – I invented a new mechanism to blow really big soap bubbles under computer control, for fun and the joy of seeing people’s faces when they operate it. This project was the focus of my artist residency at the CAD software company Autodesk, Inc.

Other engineering-related content on this website.

Articles I’ve published on Instructables.com