“Giddy” cannot begin to describe my feelings upon learning, on Thanksgiving, that I have been selected to be an Artist In Residence at Autodesk’s Pier-9 dream-lab in San-Francisco.

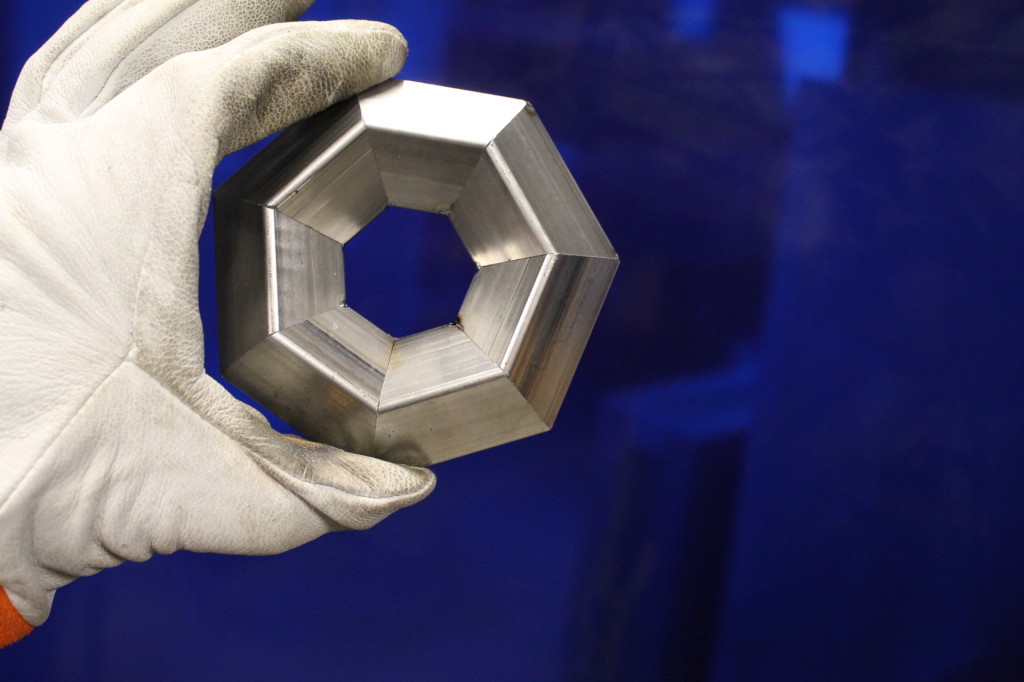

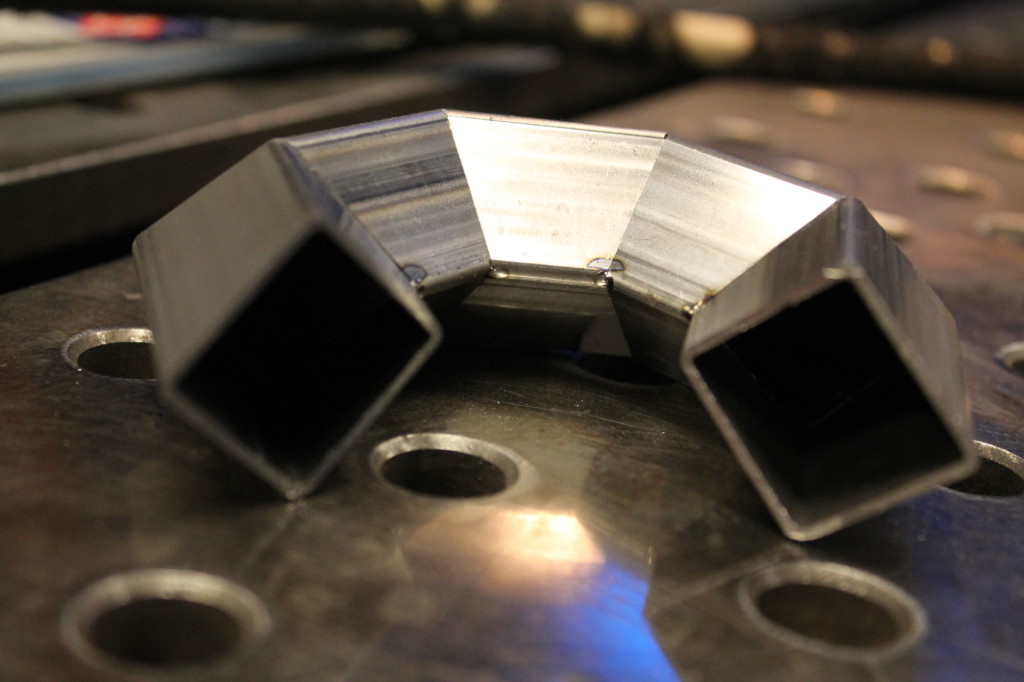

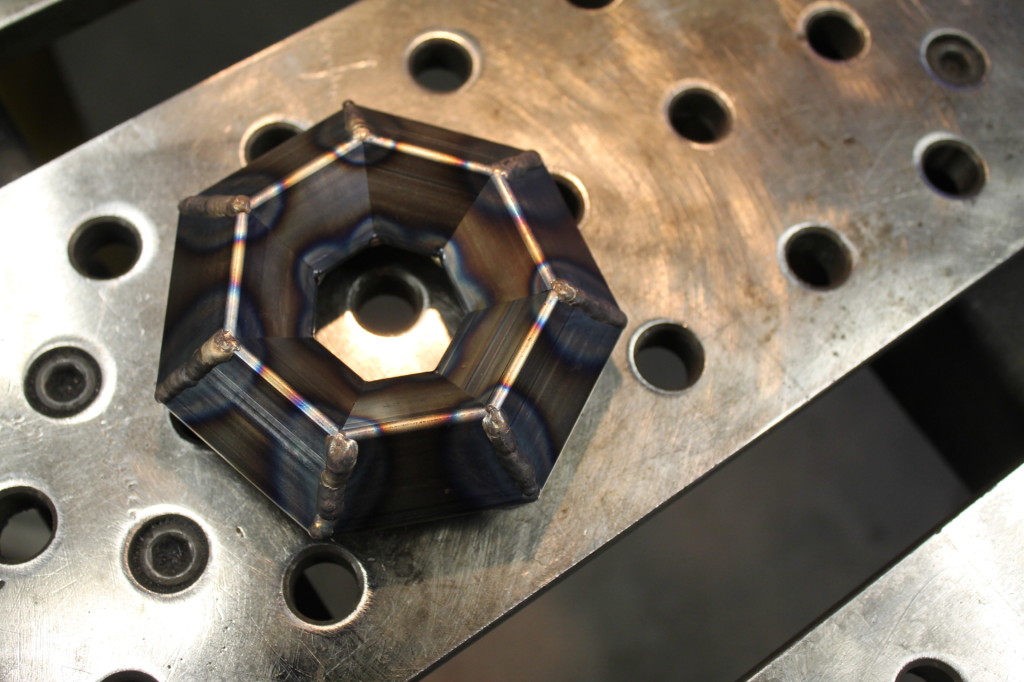

The concentration of brains, initiative, creativity, and capability in that space is stunning. In close approximation to Tony Stark’s workshop (from the movie Iron-Man) — a dream-shop with some of the most capable robotic fabrication equipment and tooling in existence including 3D printers, water-jets, lasers engravers powerful enough to work with metal, multi-axis milling machines, and more — it goes far beyond simple awesome tooling to be, from what I gather, a collegiate atmosphere where everyone is extraordinarily motivated to learn, make, and do things that push the limits of creativity, and in a context where the expected norm is to share and disseminate knowledge through the Instructables knowledge sharing website platform. Buzz Aldrin (Astronaut of Apollo XI moon-landing fame and the second person to walk on the moon after Neil Armstrong) was hanging out there testing a functioning magnetic repulsion hoverboard a few weeks ago, for instance. To be included in the cohort of selected artists for 2015 is a huge honor and inspires me to the grandest ambitions. Thank you, universe. Thank you, Noah. Thank you, Vanessa. Thank you, Mary. Thank you, Karen.

PIER 9 AiR PROGRAM from Pier 9 on Vimeo.