A tale of how I learned to weld

I frequently describe learning to weld as one of the most empowering breakthroughs in my growth as a designer. All new fabrication skills open new opportunities to dream a little (or a lot) bigger, and welding suddenly let me see much more of the sorts of things around me as achievable by my own hand.

In general, I like to work on a principle that if I can find a way to enjoy the practice, the result will be both better and more authentic. (This is key not only to welding, but any skill). So I set out to find fun little excercises to practice welding on.

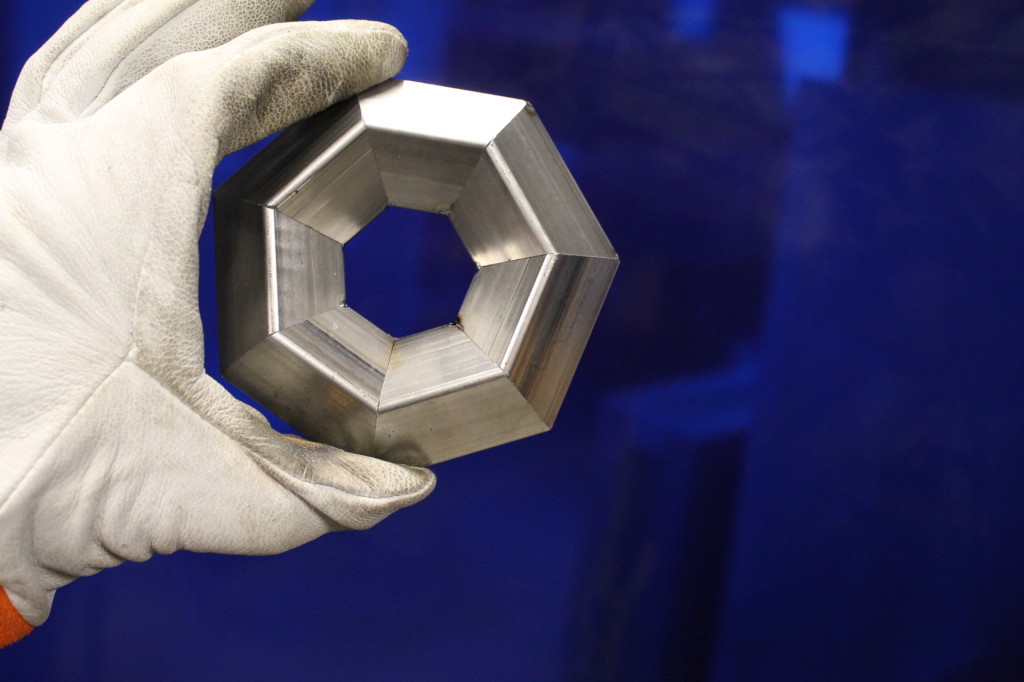

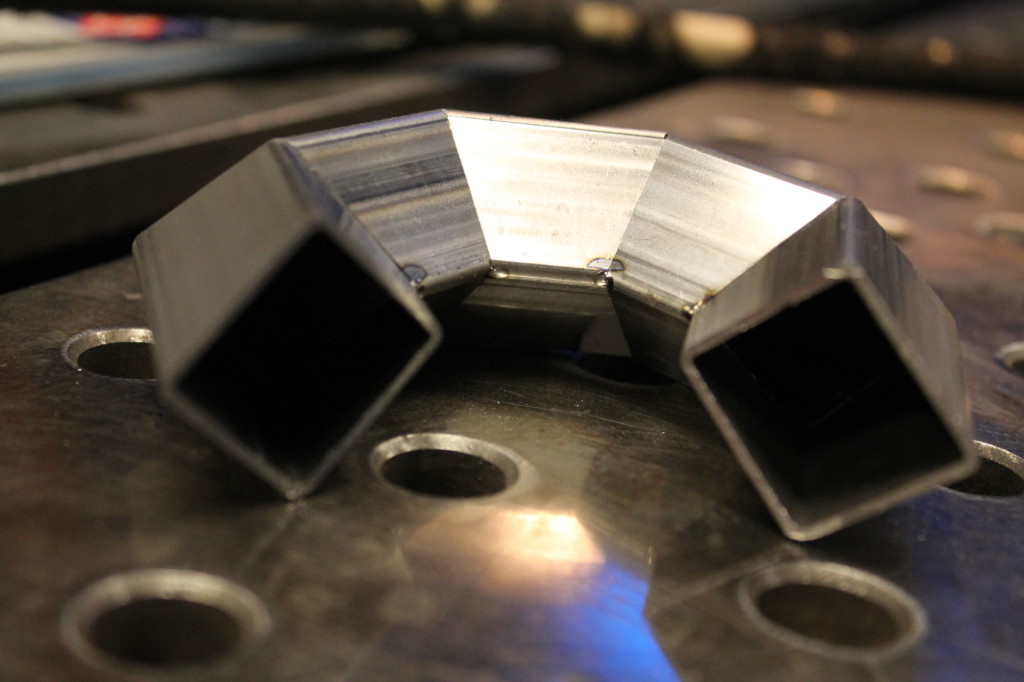

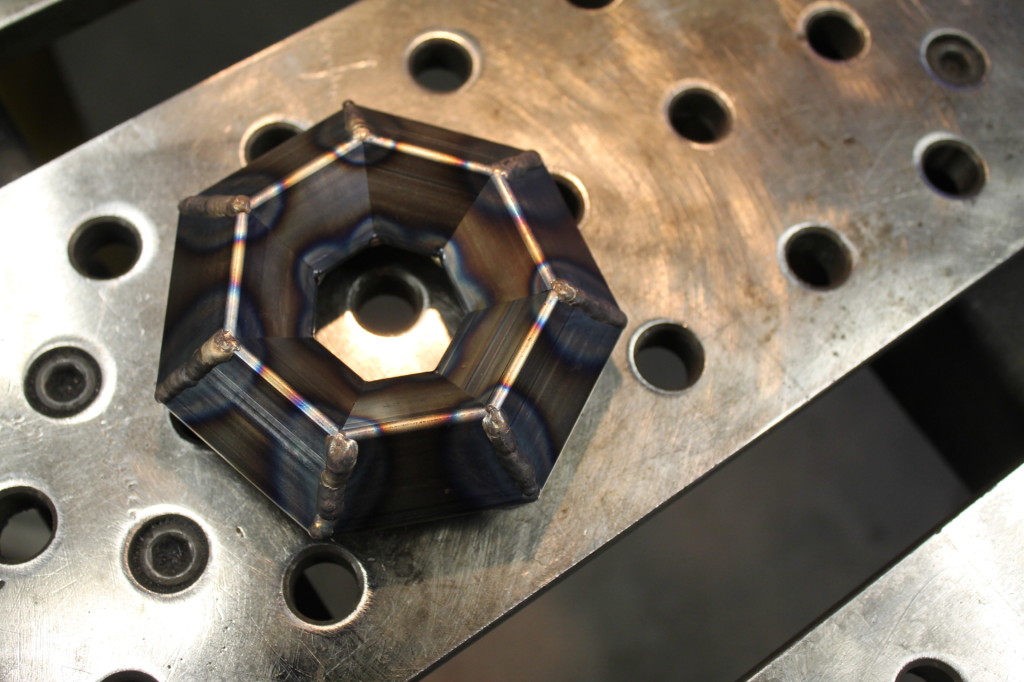

One of these excercises was making rings from square and round tubing. If you have a saw that can cut accurate angles repeatably, it’s easy to turn out a set of parts that will fit into a nice ring, with lots of seams to practice welding together. Below are the first such rings I undertook, when practicing TIG-brazing mild steel rings with silicon bronze filler metal. Along the way, I realized with delight that here was a great excuse to destructively test something, too. Thus, the video at the bottom, which shows one frame per hydraulic-pump-stroke, as I crushed the first ring and observed its failure modes.