Grey Iron and Ductile Iron Pipe are the dominant conveyances of water and sewage in American infrastructure. These types of iron have carbon and iron constituents whose relative distribution and crystal sizes determine their mechanical properties. Over time, this material are susceptible to ‘graphitization corrosion’ in which either graphite particles migrate and aggregate (typically at temperatures above 800F) or in which local electrochemical corrosion at room temperature results in preferential loss of the iron / ferrite constituent of the matrix. When this happens, the pipe becomes brittle, and mechanical insults like vibration or thermal stresses can exceed the flexibility of this now brittle material, leading to brittle failure and cracks. However, this corrosion can be invisible, because the remainder graphite particles are cohesive and the pipe appears physically unchanged.

During road work, construction, and maintenance operations, these pipes are visually inspected, but because pipes experiencing graphitization corrosion often look physically unchanged – the graphite material remains in the same contour as the original material, a method of detecting the change in properties of the pipe was needed which did not depend on visual changes, or subjective “bang on it with a hammer” subjective methodology, as was the state of the art previously. We needed a non-destructive method of detecting the changing properties of the pipe.

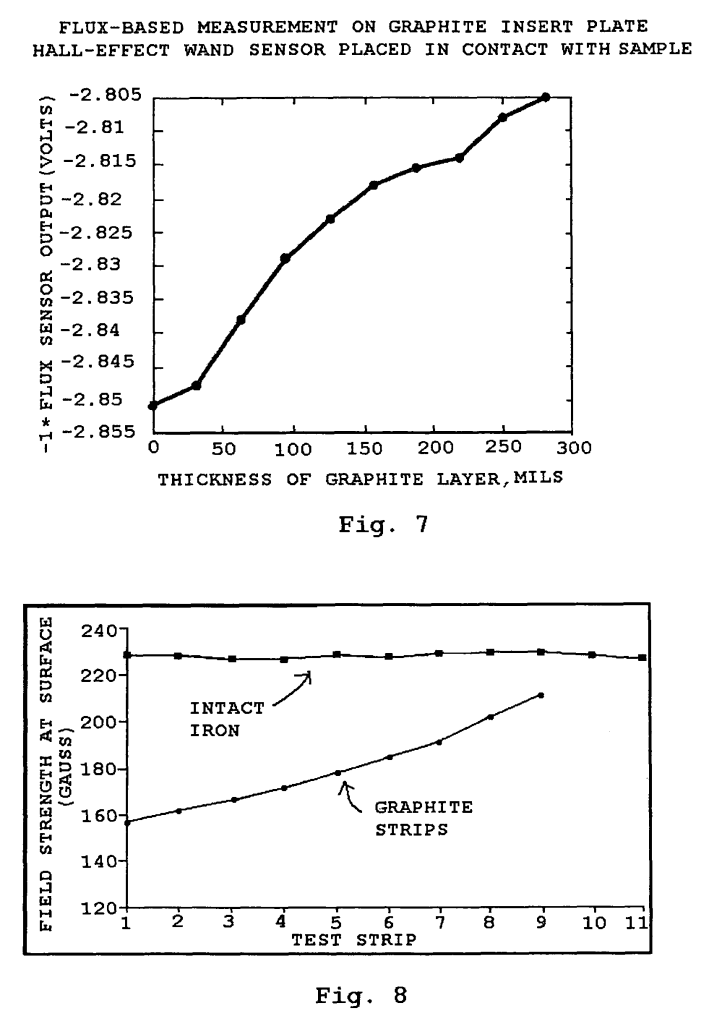

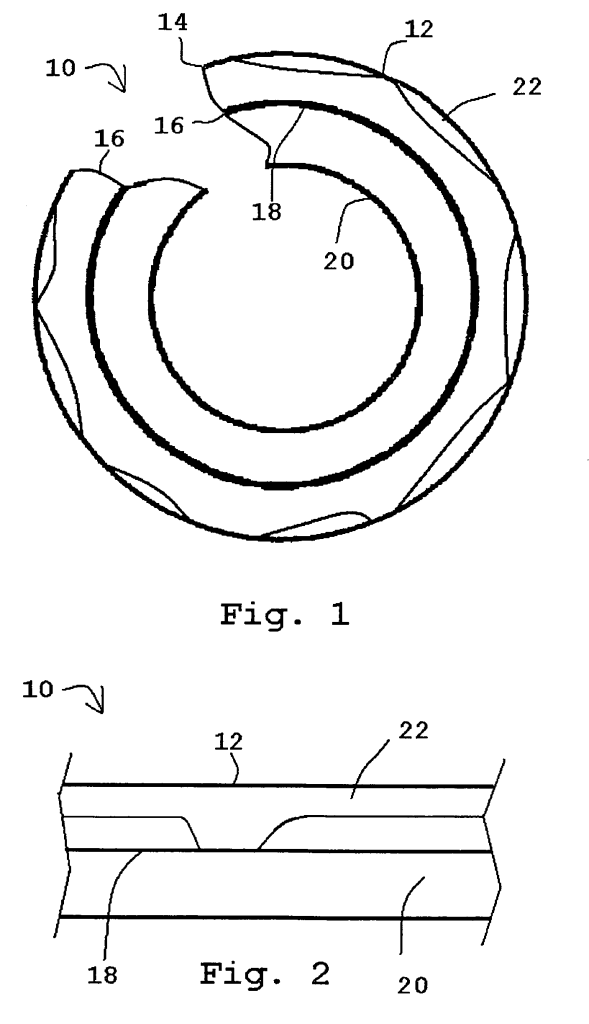

The insight of this patent is that the changing microstructure of the graphitized material has reduced magnetic properties due to the loss of iron. This could be sensed by measuring the magnetic permeability of the pipe, or it’s consequential magnetic measurements like inductance or the force developed within a fixed magnetic field. At the urging of my mentor Dr. Mehrooz Zamanzadeh, President and Principal Scientist of Matco Services, and with my assistant Sam, I developed a prototype sensor and confirmed that magnetic flux concentration, magnetic force, and inductance measurements are all viable methods of non-destructive detection of changed microstructure and ferrite loss in grey iron and ductile iron pipe. US Patent 8154279 was issued on April 10th 2012 for “Non-destructive testing apparatus for the detection of graphitization of iron”